SATS case study

SATS unlocks profit potential with Cohelion's ABC solution

Unlocking profit potential with Cohelion's ABC solution

The ground handling industry is known for its small margins so any chance to improve the bottom line in ground handling operations through the advancements of technology makes good business sense for handling companies.

Pictured: Ranjiv Ramanathan, Global Head of Special Projects, at SATS

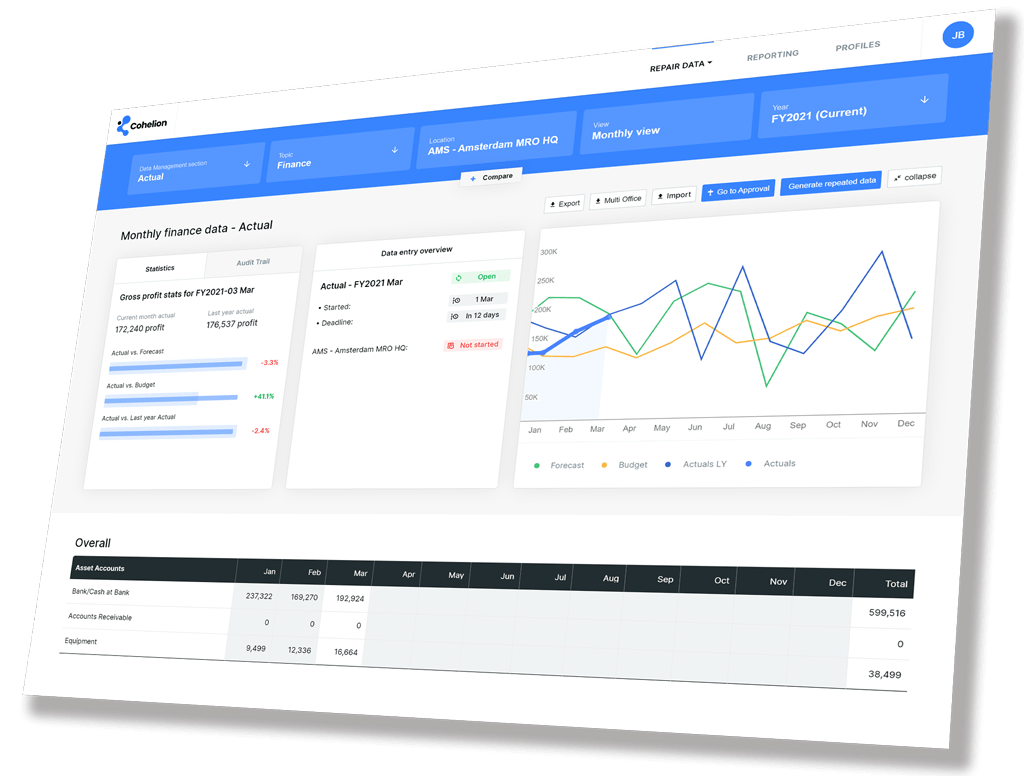

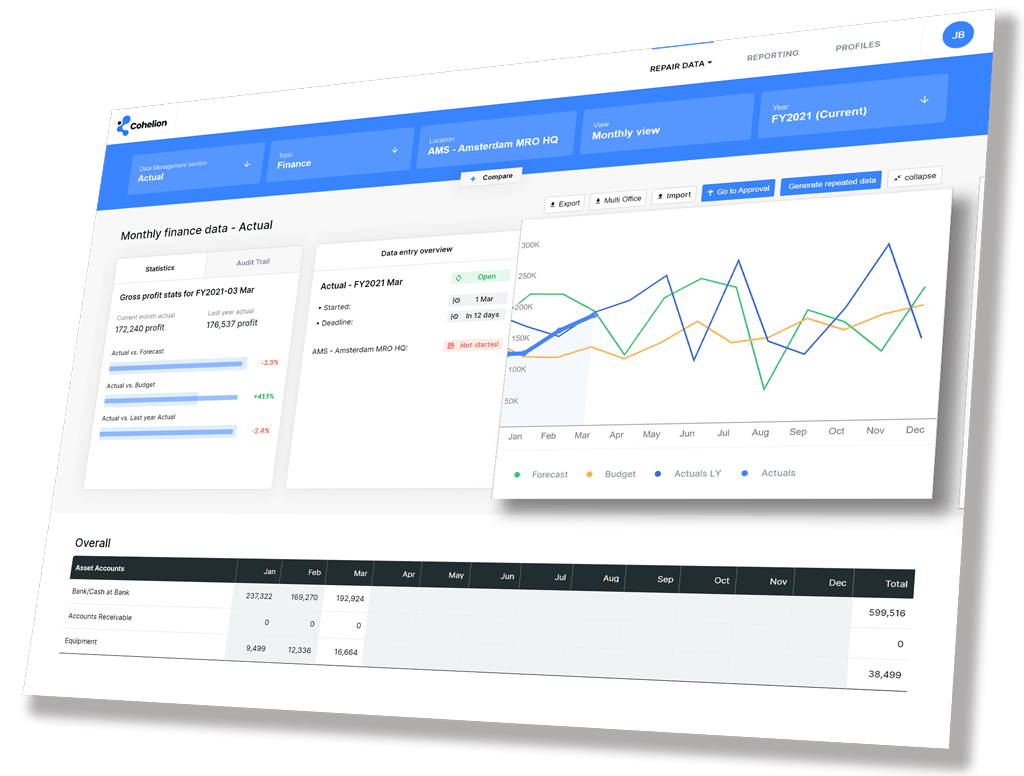

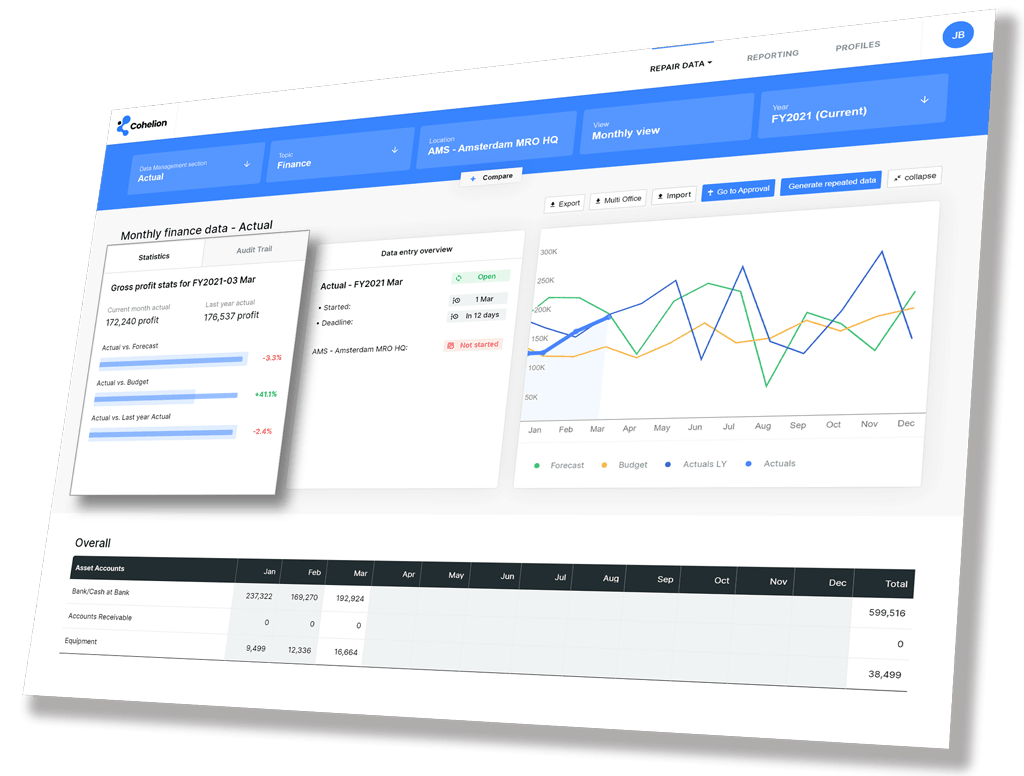

This is why SATS has chosen to implement Cohelion’s effective Activity Based Costing (ABC) solution for it’s below wing operations in Singapore, to improve visibility of the cost to serve its airline customers. “Our business is always driven by two key levers: one is the cost to serve and the other one is the correct handling rate per aircraft to commensurate the work and activities involved, especially if the flights are arriving/departing during peak operations or if additional resources are required to turnaround an aircraft faster.

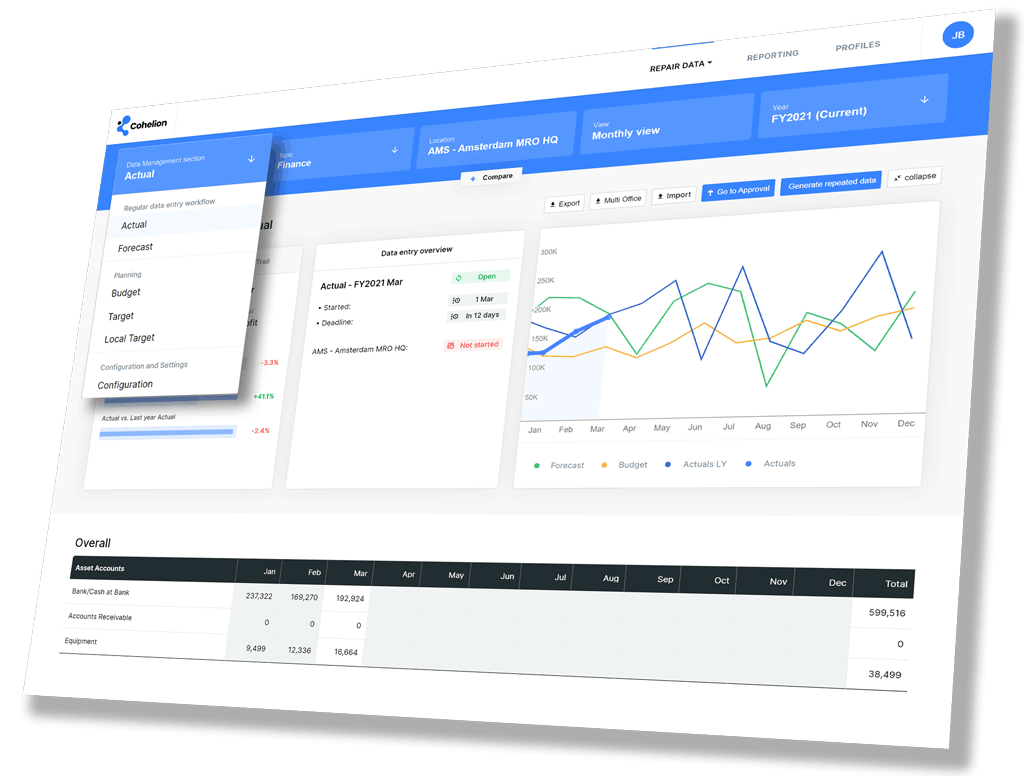

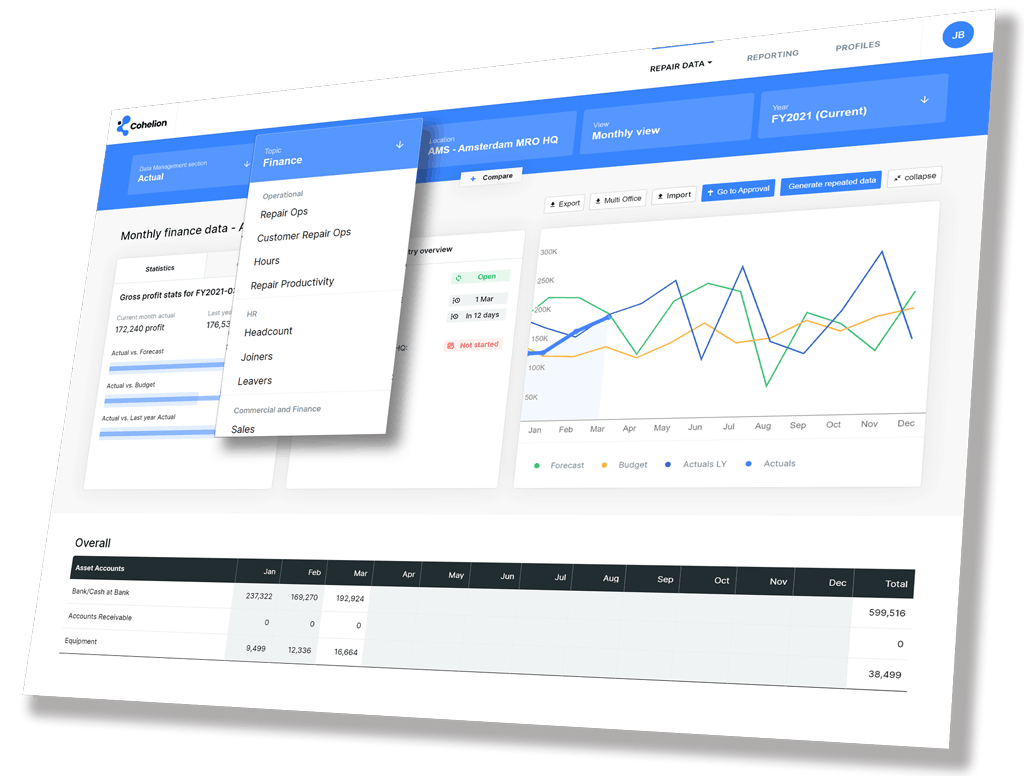

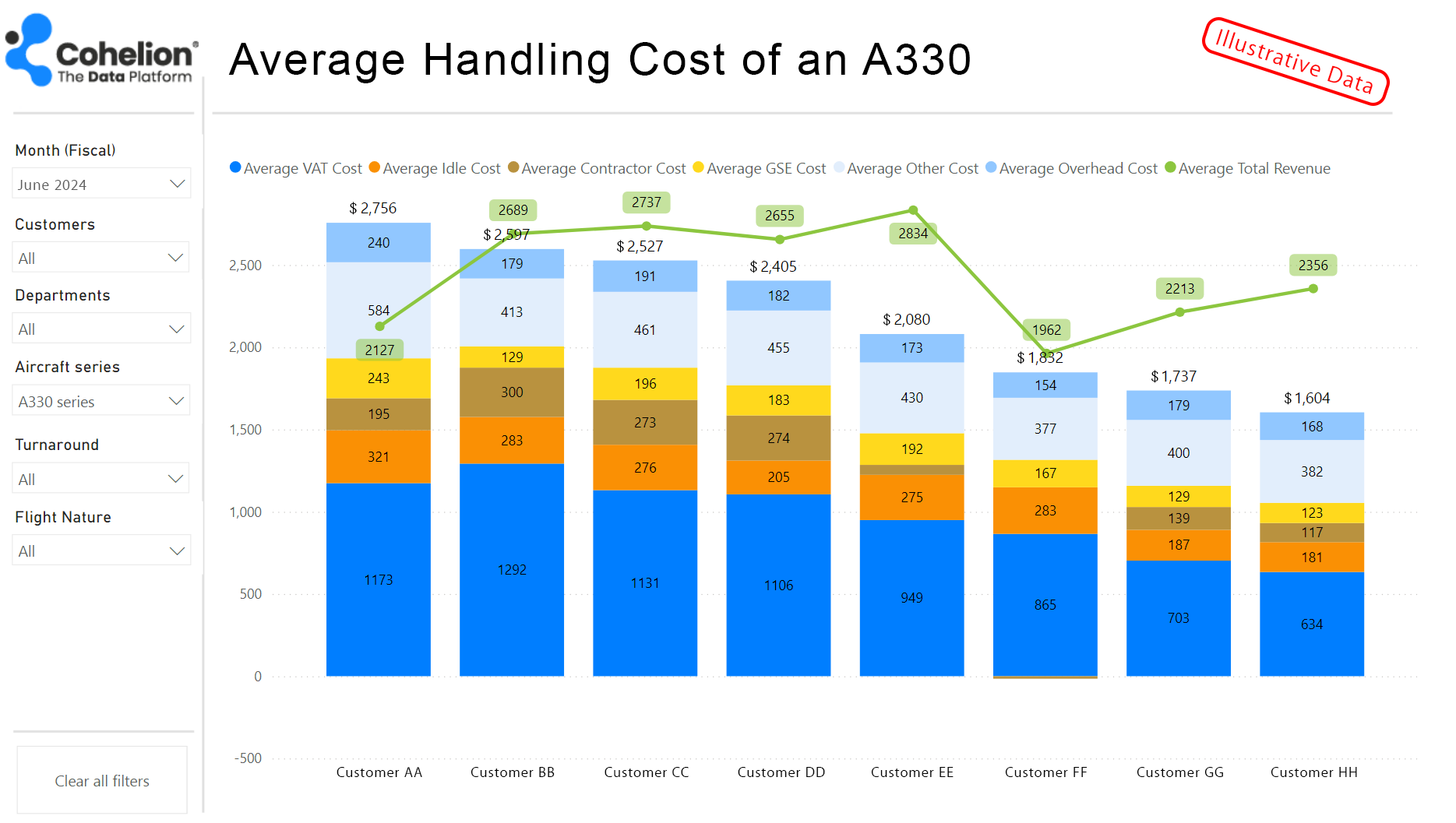

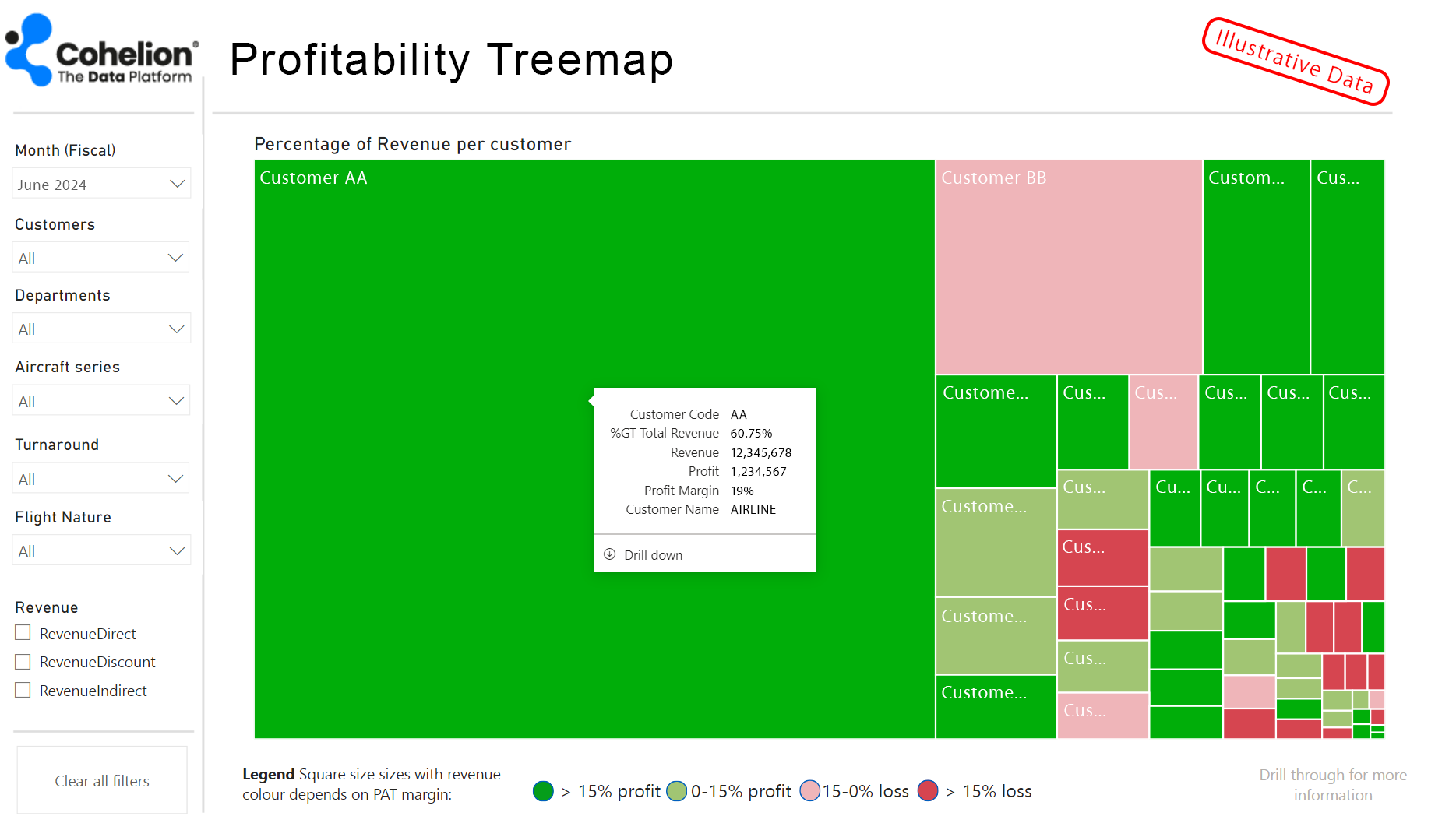

Hence we focused the activity based costing solution on below wing operations, since various departments are involved. “Understanding the levers that impact the profitability of our business are key as it allows SATS to make informed decisions on what to focus on. For example, are we charging correctly for the service? Is the cost to serve reasonable? The ABC solution from Cohelion, developed with the tonnes of data from SATS’ operations/ systems allows us to get detailed insights and develop targeted action plans to address these issues.

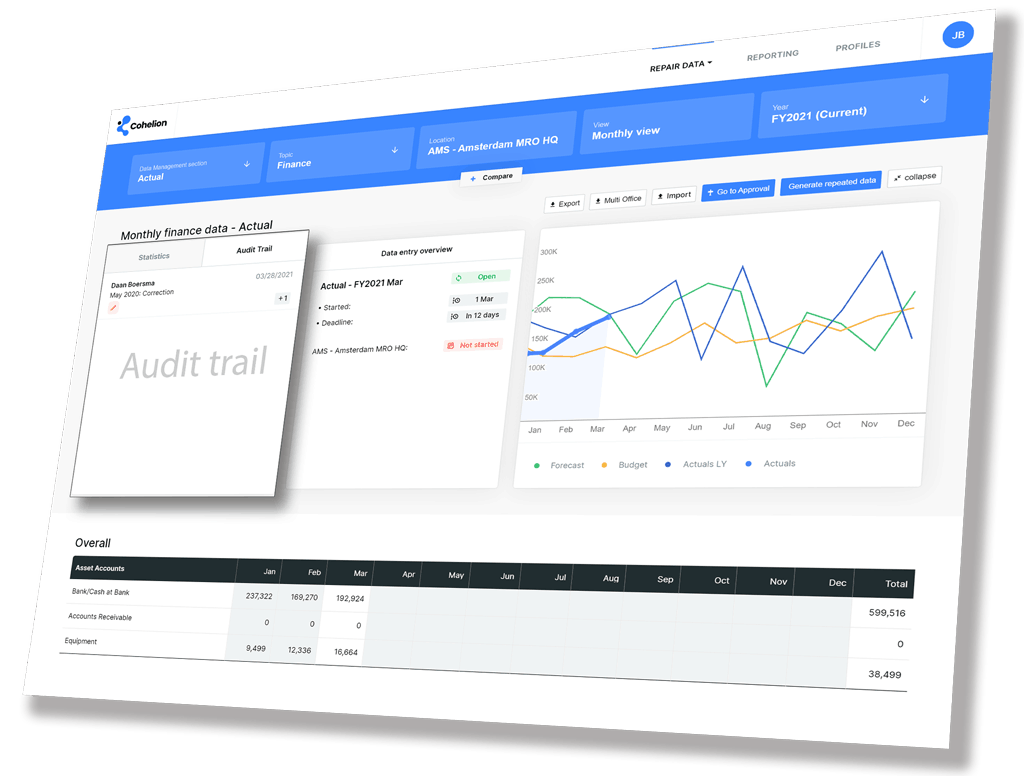

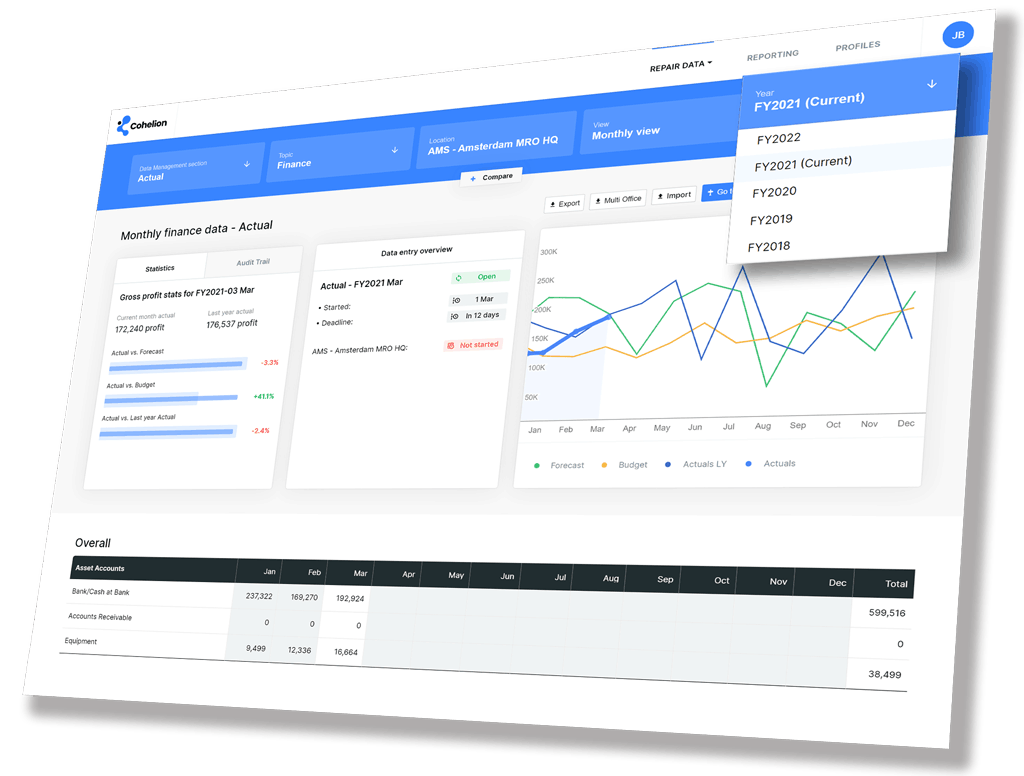

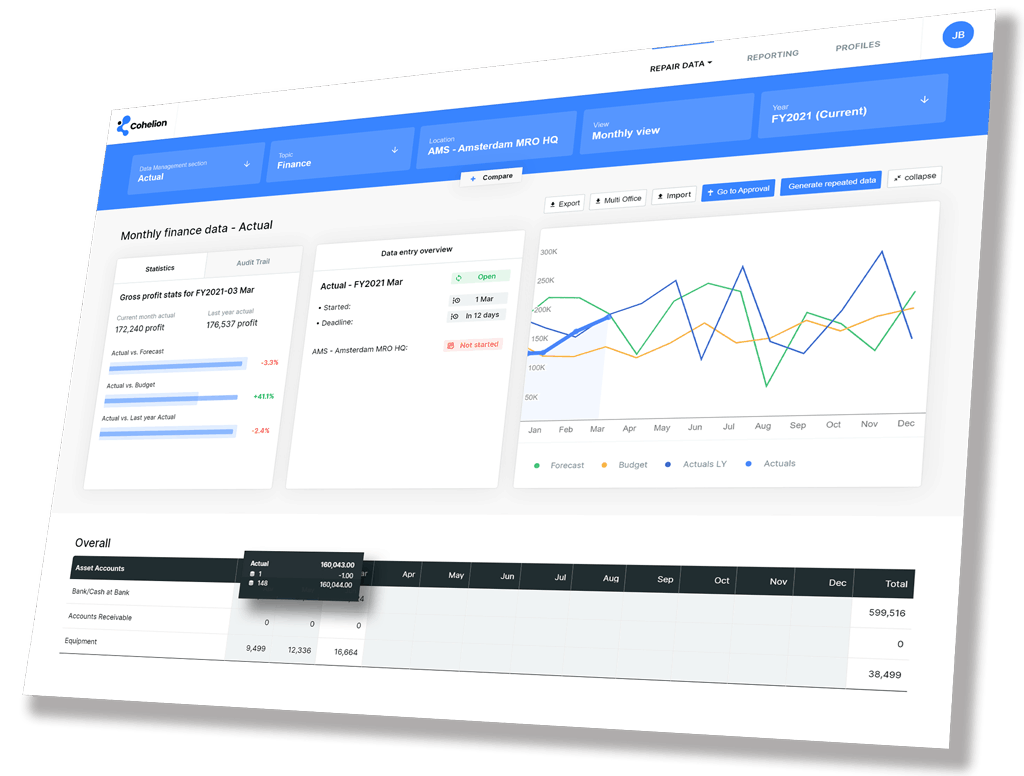

More importantly, it also allows us to monitor if those action plans have translated to concrete outcomes as this can be easily monitored via the ABC dashboards, which compares the profitability of it’s customers/operations month on month,” said Ranjiv Ramanathan, Global Head of Special Projects, at SATS. “It’s moving away from the traditional approach of having someone’s experience in how commercial rates are derived and negotiated and to use more scientific data to say ‘yes, okay, you’re saying $1,000 is the best rate, it’s the standard rate that everyone is charging’, but does that $1,000 then earn us a decent margin for the handling of a particular aircraft type and the additional services requested, more so if it is operating during the peak?”

The benefit of having ABC, says Ramanathan, is that it allows handlers like SATS to take into account nuances that can affect the overall costs of operations. Impact from higher overtime costs and idle time costs related to off-schedule flights, or increase in wages that may have been higher than the typical annual escalation in handling rates that can clearly be measured and monitored from the ABC platform, 24 by 7. SATS has implemented the ABC solution for all the below wing operations of ramp, technical ramp, baggage, aircraft interior cleaning, weight & balance, flight operations, and maintenance centre for GSE.

This allows key users to familiarise themselves with the ABC dashboards to learn how to use information made available to them. He explained that SATS started with a Proof of Concept to address the key question of what amount of costs could be directly allocated to a flight, which turned out to be around 70%, a fact not known before the POC. “If you combine the direct and indirect costs, and we were quite clear that this was going to ensure that we could easily even go down to a flight level to assign those costs, it was a no brainer for us then to move to the full implementation of the ABC tool,” he said.

Benefits of activity based costing

When asked why the direct cost was so important, he said: “The biggest benefit with the ABC’s tool is that you’re pulling information automated on a daily basis from all our various systems: our deployment systems, GSE telematics, time and attendance, payroll systems’ you don’t need to depend on manual inputs or waiting for someone to provide that information. There is no ambiguity in the data because it is coming directly from the systems that operations use to deploy manpower, equipment and HRIS systems to provide attendance and payroll information. “Whatever you decide from today applies tomorrow, applies one year down the road, there’s no change in parameters unless somebody decides to change it; there is always consistency with how direct costs are computed.”

While the high percentage of cost allocation was the main driver to moving to full implementation, it was the level of visibility across their whole operation which was very impressive for SATS. “With that kind of visibility, it also allowed us to analyse profitability, not just by customer, but down to aircraft type or even per flight or even per department. This is something that we would have struggled to collate and compare previously,” he said.

Two key users of the ABC tool are the commercial/marketing teams, and operations team. “Both will see the same information e.g. the bottom five customers by profitability and then deep dive into their respective areas of expertise. Commercial teams will use the ABC to compare the handling rates against a benchmark for the same aircraft type, while ops will analyse the cost to service against a benchmark for the same aircraft type.”

Future plans

SATS will roll out the ABC solution to other aspects of the operations e.g. above the wing so there is a holistic ABC view of the operations, that will make it easier to scale the solution to similar operations overseas.

This article was written by Samantha Payne for the June edition of the Ground Handling International magazine.

Activity Based Costing

The direct impact of operational cost drivers on customer profitability

Besides this case study, Ranjiv Ramanathan also presented the first launch of our Profitability Analysis business solution at the Annual Ground Handling International Conference of 2023 in Lisbon. Watch the full presentation now and see how SATS is now able to easily detect and act on revenue losses, but also revenue opportunities.