A WFS case study: Workforce Optimization

Worldwide Flight Services (WFS), a member of the SATS Group, has taken a major step towards incorporating machine learning into its workforce data analytics thanks to an unique partnership with software company Cohelion.

Gone are the days of laboriously inputting workforce planning hours into an Excel sheet from multiple platforms leaving room for human error. Every manager in the cargo world needs to balance the demand of incoming cargo with the available workforce on site. With Cohelion’s Workforce Optimization (WO) software solution this process will now be automated and standardized across the EMEAA network. The optimization software will be rolled out to all operational excellence (OE), HR and IT departments across 13 EMEAA countries and 40 different stations as part of a two-phase project with two main aims: 1) improving forecasting accuracy of cargo volumes, and 2) maximizing resource allocation as per customer demand.

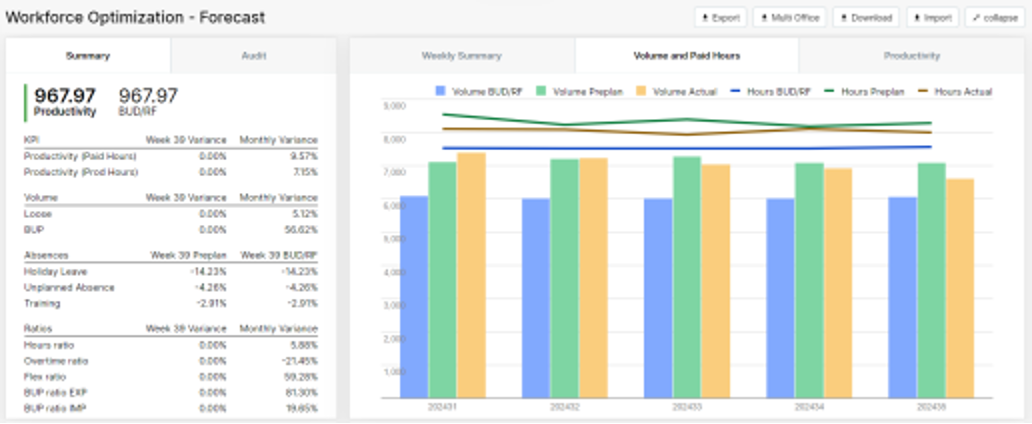

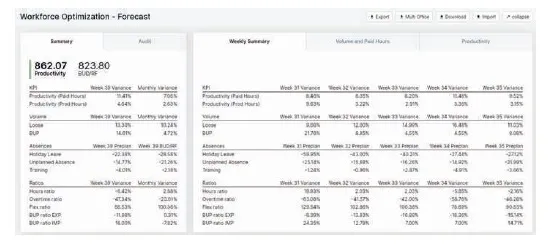

The project is currently in its first phase of implementation from transitioning local Excel files to a centralised data repository of weekly and monthly forecasting data for the region. The second phase will incorporate machine learning which will enable the system to produce an optimized forecast by airline, by day, based on known schedules, historical data and current trends. To do this WO teams will collect various types of operational data from their systems including up-to-date airline schedules, trucking activity over the same period, cargo tonnages, cargo type and air way bill (AWB) data.

“We then combine it with workforce data from our various roster management systems across the region including payroll hours, productive hours, absenteeism, and key ratios,” said Sonny Boateng, Workforce Optimization Manager EMEAA. “Workforce allocation is the initial step to ensure and service quality, and we believe service quality will greatly improve as the accuracy of the forecasting improves. Machine learning will automate and give more precise predictions of cargo volumes and workforce requirements, which is an intelligent approach allowing us to be more nimble as a business in a sector that is ever increasingly driven by the consumer demand sector. Data-driven decision-making, powered by Cohelion, has become a core component of how we adapt to market challenges.”.”

“We have evolved with Cohelion from basically capturing metrics and KPIs to starting to introduce elements of predictability,” said Pedro Garcia, CIO EMEAA, at WFS. “In the case of Cohelion, it’s not an agnostic BI, it is bringing deep knowledge of the cargo industry. Cohelion can assist with master technologies like machine learning and data models and has an understanding of the industry, bringing real value compared to other IT companies.

“The old way of working depended on people entering data consolidated from two or three or four operational and HR systems dealing with data compatibility and discrepancies,” explained Jimi Daniel Hansen ‒ Senior Vice President Operational Excellence EMEAA. “Doing this was both, of course, time-consuming but also reliant on people doing it correctly and adapting it correctly. So we wanted to make sure that the data was retracted automatically, to have one side of the truth for everybody both on hours and tonnages in order to have a more standardized and digitalized system in place. This is what the current phase of Workforce Optimization delivers,” before adding that, “We are certainly not doing workforce optimisation to cut costs, we’re doing it to make sure we have the correct workforce as per demand from our customers to ensure service quality.”

Boateng said: “Part of our mandate as WO within the OE department is to ensure that the workforce allocation is adequate to meet our customer service expectations. Traditionally, cargo volumes are extremely volatile and difficult to plan for. But even in volatility there are trends, so our approach in this scope was to forecast the expected workload based on the most current schedules and historical trends. So the pre-planned forecast data forms the pinnacle of our operational planning. We evaluate variances between budget versus pre-plan and then we also evaluate pre-plan versus actuals. We want to identify key drivers of variations to helps us improve both the workforce allocation and the service quality going forward. By predicting cargo volumes and workload, we can better plan necessary workforce up to exact task requirement and associated skillset required for those tasks.”

Understanding patterns to improve service quality

In order to react to different tonnage trends there needs to be a certain amount of flexibility in the workforce, continues Hansen. “That certain amount of flexibility comes from either third party, subcontracted or our own staff not on full-time contracts, depending on the countries. In the EMEAA region there are 13 different countries, 13 different ways of working, 13 different labour laws and rules and aircraft profiles, which we had to amalgamate to make sure that the system worked for everyone,” he said.

Hansen is keen to stress that they are not using this optimization system to only improve productivity KPIs. “We’re really using this tool to better manage expected demand, to make sure we’re not overstretching our staff and having the correct number of staff at the right time because in the end that will give us a better service quality towards our customers,” he said.

Boateng says he’s looking forward to being able to forecast peak and off-peak trends. “This is where the flexibility of our workforce planning is tested the most. So I am looking forward to us being able to understand patterns and off-trend events in cargo volume to better align our resource allocation,” he said.

Beyond financial planning

Garcia added that the workforce optimization solution has not been developed for financial planning purposes either but as a tool to help operations, taking a bottom-up approach. “The beauty of the Cohelion product is that we are just moving one level down with a much lower level of granularity,” he said. “It is not financial planning, it is an evolution that it is going one step forward that is workforce optimization. It’s going to the lowest level of granularity with the models including algorithms that reflect whatever the dimensions may be: delays, airline or aircraft typology, seasons and so on. Thus creating a forecast that actually reflects the business. This is the beauty of the product and this is the main difference from many other financial planning projections and predictability solutions that you see with other handlers.”

Hansen expands further by adding: “If tonnage increased 20% that is one factor to consider for financial planning but for operational planning we still need to know if it’s on a belly flight, is it on trucks? Is it on a full freighter? Because this is where we will be able to plan it correctly because if all of these 20 tonnes comes in one day that’s spread over seven days, you know, that’s the difference. The shift from traditional planning to data-driven decision-making has not only improved our operational efficiency but also reduced costs.”

Engaging stakeholders for workforce success

There will be adoption of the workforce optimized solution across multiple departments within WFS from OE, IT, Operations, finance, HR, and training to name a few. All of these departments will be included in workshops and practical single focus sessions to help users and members of the operational planning meetings utilise the data and insights for their daily contributions to service quality.

“Ensuring buy-in from key stakeholders involved early stakeholder engagement. Involving key stakeholders, primarily the WO managers and operational directors, early in the decision-making process, design and user acceptance testing where issues were tracked allowed us to gather input and address concerns before the final product was launched. So in essence it was a user defined system rather than a system appointed to users which really makes the difference,” added Boateng

This article was written by Samantha Payne for the October edition of the Ground Handling International magazine.